Laser Cutting System

Fami adds a new piece to the mosaic of investments for technological development.

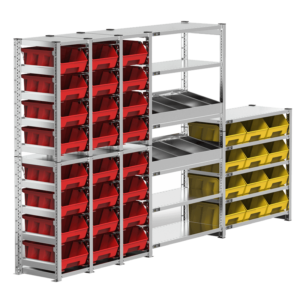

The new ML3015eX- F40 Fibre Laser Cutting System by Mitsubishi represents a new piece added by Fami to the great mosaic of investments for the technological development and growth of the quality standards of the industrial furniture production, logistics systems and the outfitting line for the commercial vehicles of its Store Van brand.

Cutting accuracy and highly reliable performance: the innovative fly-cutting technology introduced in the production plants of Rosà (VI) is not just the last important economic investment made, but also represents a great added value for the optimization of the production organization. The top performance and advanced integrated automation systems of the new ML3015eX- F40 Fibre Laser Cutting System by Mitsubishi substantially reduce production times and costs, allowing the streamlined use of human, energy and environmental resources, to the benefit of the competitiveness of the product.

The excellent cutting beam and the remarkable 4000W power are the fundamental characteristics of the new laser 2.0 technology that allows cutting components in small batches and complex shapes, thus meeting the most demanding requirements. The system can handle sheets of up to 1500×3000 mm, which guarantees the production of all Fami and Store Van products.

In addition to the innovative laser cutting technology, the new ML3015eX- F40 Fibre Laser Cutting System by Mitsubishi boasts a compact tower automation system with a six pallets capacity, a plant height of 5,350 mm and the ECO mode, which reduces energy consumption by up to 99% during the machine standby phase.

Fami, therefore, continues challenging the market by investing in cutting-edge technology in order to produce the most advanced solutions to meet every specific technical need and achieve increasingly higher levels of productivity and competitiveness.