From 02nd to 03rd October, Fami will take part in Bricoday in Milan, Italy

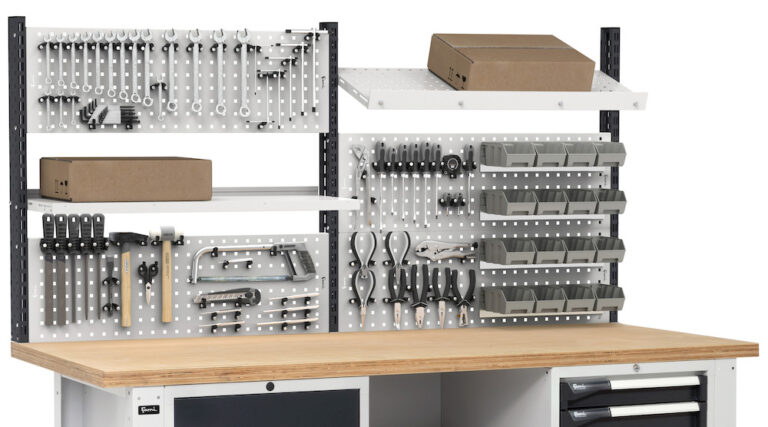

Work Look workbench panel

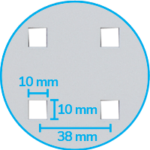

The workbench panel with 10x10 mm square hole is an innovative and multipurpose component that can be used in 3 different ways based on the position in which it is fixed.

Multifunctional: perforated panel or shelf

Installation on uprights

Wide range of accessories

| Width (mm) | Depth (mm) | Height (mm) |

|---|---|---|

| 953 | 40 | 304/ 456 |

| 953 * | 31 | 152 |

| 1438 | 40 | 304/ 456 |

| 1438 * | 31 | 152 |

| 1938 | 40 | 304/ 456 |

* Electric perforated panel

Work Look workbench panel: benefits and features

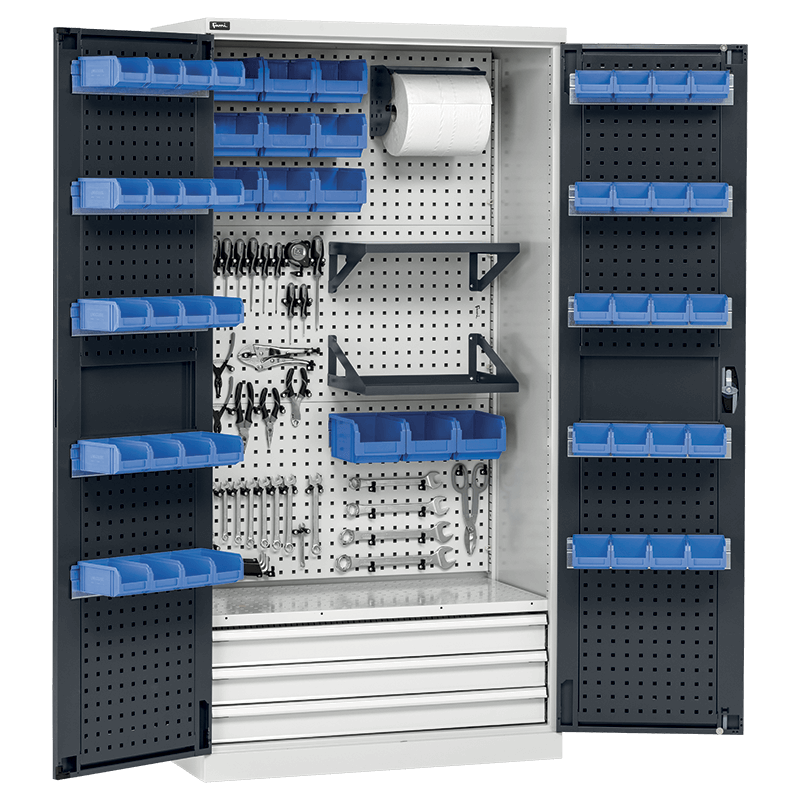

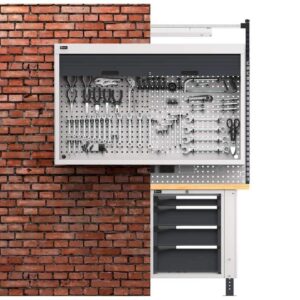

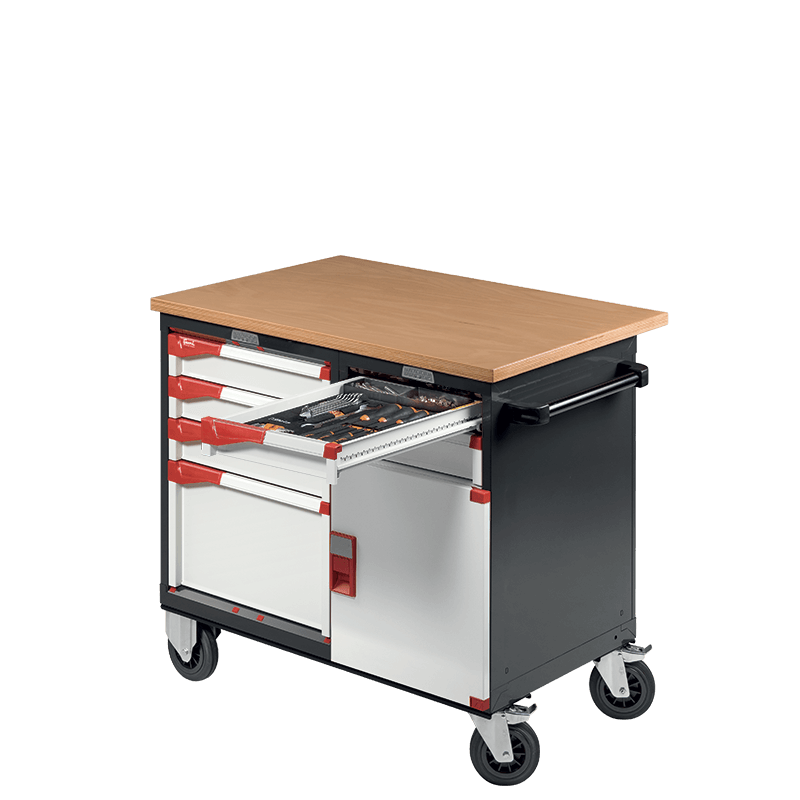

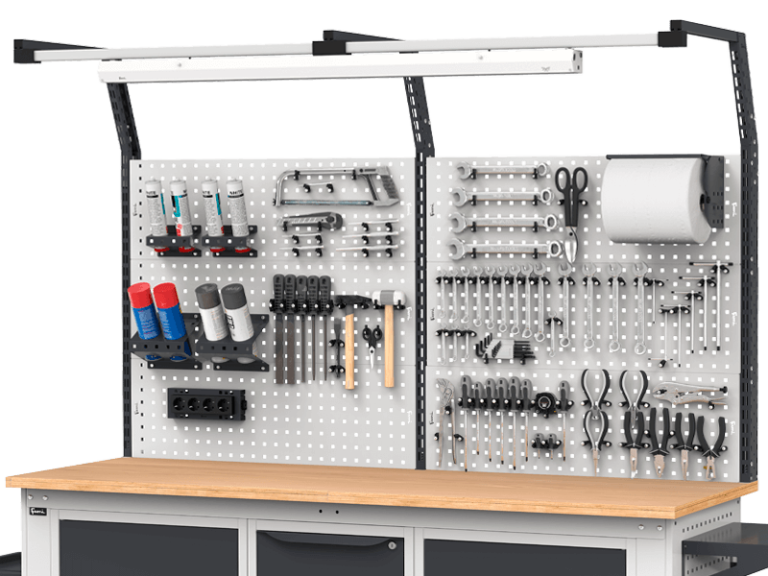

The tool bench can have a single perforated panel or a combination of perforated panels and shelves. The panel is designed for installation on uprights in a vertical position as a tool panel, or a horizontal and inclined one as a shelf for objects or bins. If used as a shelf, the practical box-stop edge at the end creates a containment edge that prevents the stored material from falling, ensuring safety and protection.

The workbench with tool holder panel can be set up to create a system capable of supplying electricity for recharging battery-powered tools and for lighting the workstation. The Electric panel, in fact, has special notches on which to install multi-socket strips, USB sockets and circuit breakers quickly and easily. All you need to do is to connect these electrical components to the network using the appropriate cable to provide the tool bench with a power source.

The tool bench can also be equipped with solutions such as cabinets with roller shutters and wall units with Vasistas opening to store tools and components away from dust and dirt. These elements are fixed directly to the perforated panel or via a pair of brackets that allow you to position the cabinets and wall units at different heights to leave more free space on the perforated tool panel.

The tools and work instruments can be freely positioned on the perforated panel using a wide range of components such as accessories and tool hooks. Spray can holders, shelves, bars with hopper-type bins and Unipok hooks are fixed to the tool panel using a fastening system consisting of plugs and screws. This installation method is not fixed and static, but flexible, allowing the operator to remove or move an accessory or hook based on the work material to be organised in the square hole panel.