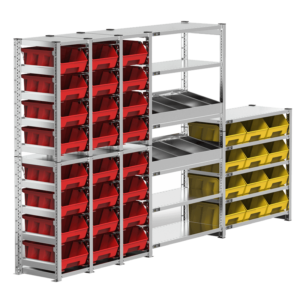

Dynamic shelving units

Dynamic shelving units are an indispensable element to ensure an easy and continuous flow of goods and material both at the workstation and in warehouse logistics.

- Roller rack with 4 tilting frames

- FIFO method: First In, First Out

- The frames can be independently tilted from 5° to 30°

- Set up for wheels

- Shelves with depths from 321 to 821 mm (load capacity 100 kg each)

- LIFO method: Last In First Out

- The shelves can be independently tilted from 5° to 30°

- Box-stop edge to prevent bins from falling out

- Shelves with depths from 521 to 821 mm (load capacity 300 kg each)

- FIFO method: First In, First Out

- The shelves can be independently tilted from 5° to 30°

- Set up for wheels

The unique characteristics of shelving systems for dynamic warehouse

The reorganisation of the warehouse by using dynamic warehouses is a Fami priority. All racks are designed to access the products to be picked in a simple and safe way, optimising time and therefore costs. Made of sheet steel, they are solid and sturdy, capable of resisting the most diverse stresses for a long time.

Depending on the dynamic rack chosen, it is possible to organise the stored goods on tilting and height-adjustable shelves or frames. These components allow you to enjoy a double benefit: on the one hand they make picking the material quick and ergonomic, on the other they allow you to always have a clear view of the quantity of screws and small parts stored to be able to act promptly when stocks run out or start to run out.

The inclination of the shelf or frame can be adjusted freely by the operator using the appropriate side bracket. In fact, simply changing the position of the screw in the notch of the component will be enough to change the angle from a minimum of 5° to a maximum of 30°.

Bins of different types and sizes can be stored on dynamic warehouse racks. Depending on the picking method, it is possible to choose solutions based on LIFO or FIFO methods, important methodologies in the field of Lean Production. This type of dynamic shelving makes picking activities fast and precise as it allows you to apply the “empty – full” method: when the contents of the first container run out, this is extracted so that the next bin slides into its place ready for use.

Dynamic racking systems to optimise time and resources

Dynamic shelving units are the most suitable solution if the work activity requires a continuous rotation of products and components, as they ensure the work material will be immediately available and to hand. These metal shelves are typically positioned next to stations along the assembly lines for a quick and ergonomic access to the different assembly kits.

The particular feature of these shelving units with inclined shelves or frames lies in exploiting the force of gravity for handling screws, bolts and other components. As the products run out, simply remove the front box or bin to advance the one behind at a controlled speed so as to always have the material available without leaving the workstation. You will therefore be able to enjoy maximum visibility of the stored items and keep stocks under control to minimise waste both in terms of resources and of time.

Depending on the type of dynamic warehouse shelving unit chosen, it is possible to implement LIFO or FIFO methodologies, typical of Lean Production. Thanks to front loading, tilted shelf racks are ideal for adopting the Last In First Out methodology, while Kanban racks with dividers and the dynamic racks with rollers allow rear loading, typical of the First In First Out method.