We will be closed from 12.08.2024 to 23.08.2024

The technological partnership between Fami and Assistec

Year:

2021

Sector:

Robotics

Place:

Reggio Emilia

For over 25 years Assistec has been the reference company for electronic and mechanical assistance on CNC machine tools. Over the past few years, besides its core business, the company has focused on helping companies in their transition to Industry 4.0methodologies by developing solutions that integrate machine tools and industrial robots.

Fami and Assistec have merged their know-how to develop RoboFeed model “A”, a family of robot-controlled automations with an integrated tower magazine for feeding non-stackable parts onto CNC machines, which enriches the range of available Assistec solutions.

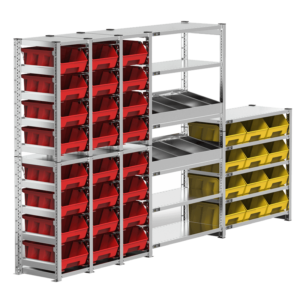

Assistec requested the services of Fami in particular for developing a flexible and “plug&play” solution for its customers: the company based in Emilia-Romagna was looking for a magazine to pair with its robot, in which to store unfinished components waiting to be machined on the machine tool and to reallocate finished parts.

The key features required from this product were:

- a large containment capacity;

- sturdiness;

- safety;

- easy to control with a robot;

- possibility of reusing the magazine for the subsequent machining phases, in line with a “lean manufacturing” approach.

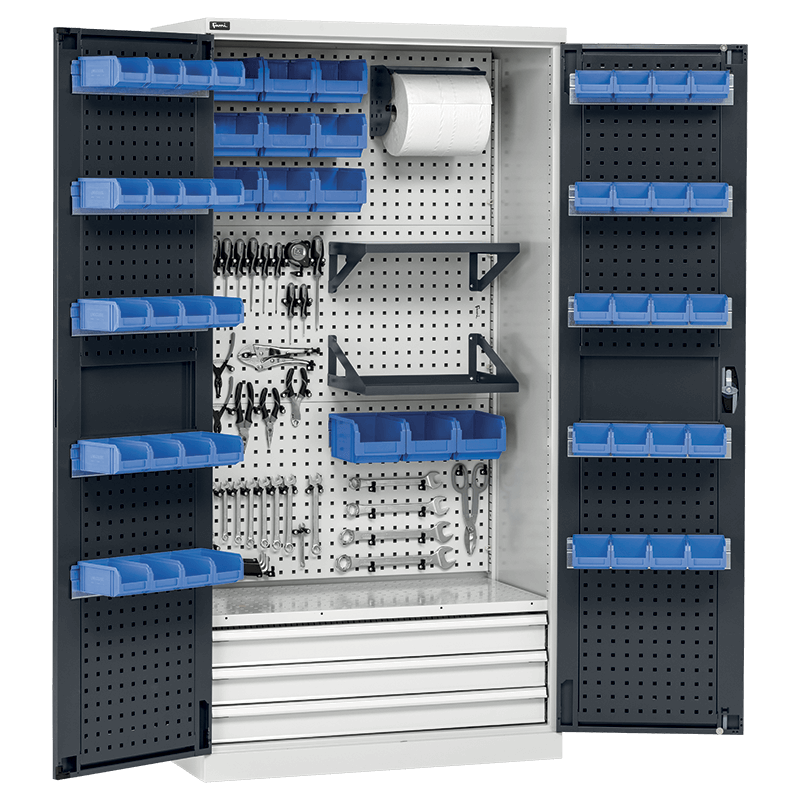

The choice fell on the Master cabinet by Fami, characterised by numerous composition options, a broad range of dimensions and a push-to-open lock that guarantees safety and is easier to open with a robotic arm.

The machine’s magazine contains the Master drawer cabinet that can be customised with up to 16 drawers, for keeping the various components to be machined, and can be easily equipped at every item changeover.

Once the machining cycle has been programmed, the robot itself opens the drawers, extracts the unfinished parts and puts the finished parts back in place – a process that saves a considerable amount of time.

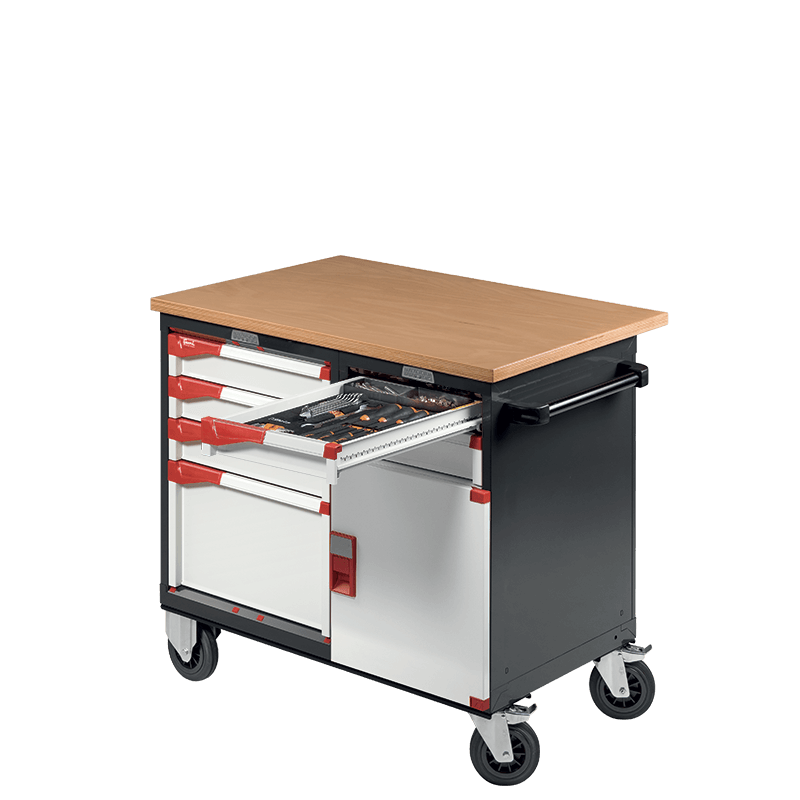

A further advantage of this system is the possibility of choosing the version in which the drawer cabinet moves directly on wheels or by means of an electric pallet truck, enabling the operator to rapidly replace the machined parts magazine with a new magazine containing the unfinished parts, or sending parts to the subsequent phases or directly to the shipment area.

Fami and Assistec have merged their know-how to develop RoboFeed

The partnership between Assistec and Fami brings several advantages in many fields: firstly, it helps the end customer to boost production and sales, reduce the cost of labour and the operator’s physical strain, and obtain a higher EBITDA value; moreover, it allows to use and implement high-quality personalised equipment and technologies, studied and designed to adapt to any need, that benefit from tax incentives associated with the Industry 4.0 strategy.